Sewage treatment is the process of removing contaminants from waste water, primarily from household sewage. A sewage treatment plant (STP) has to handle the designed quantity of sewage and deliver satisfactory quality of treated water, on a consistent, sustained basis over typically 10-12 years. This requires proper design and engineering, followed by proper operation and maintenance throughout its life.

We need an STP that:

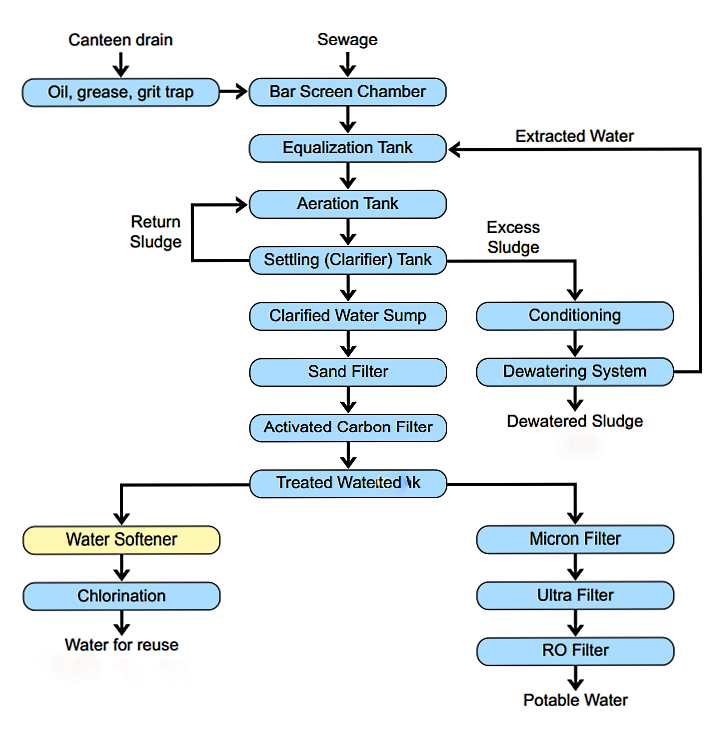

The flow chart of a typical STP is shown as under: Assured availability of water for various secondary uses, Enormous savings in fresh water costs, Lesser Environmental Degradation and Improved public Health are benefits of a well-run STP.

The role of the bar screen is to prevent entry of solid particles/articles above a certain size, such as disposal cups/glasses, polythene bags, and sanitary napkins into the STP. The screening is achieved by placing a screen made out of vertical bars, placed across the sewage flow.

The waste is placed at the discharge point of the kitchen area itself to arrest solid and fatty matter at source. The wastewater output from this unit is taken to the equalization tank. The solids and fats that are separated in this unit are disposed off along with other and grease from the wastewater at source ensures that the contact time between solids and wastewater is kept to a minimum, so that the wastewater does not absorb additional organic pollutant loads due to leaching of these substances from the solids. An oil and grease/grit trap is generally not an essential unit in a typical residential complex. It is however a mandatory unit in commercial and industrial units with a canteen/kitchen on campus.

The sewage from the bar screen chamber and oil, grease and grit trap comes to the equalization tank. The equalization tank is the first collection tank in an STP. Its main role is to act as a buffer: to collect the incoming raw sewage that comes at widely fluctuating rates, and pass it on to the rest of the STP at an average flow rate. During the peak hours, sewage comes at a high rate. The equalization tank stores this sewage, and lets it out during the non-peak time when there is no/little incoming sewage.

The aeration tank is at the heart of the treatment system. The bulk of the treatment is provided here, employing microbes/bacteria for the process. The main role of the aeration tank is to maintain a high population level of microbes. This mixture is called MLSS (Mixed Liquor Suspended Solids). The mixed liquor is passed on to the clarifier tank, where the microbes are made to settle at the bottom. The settled microbes are recycled back to the aeration tank. Thus they are retained for a long period within the system.

There are three purposes and roles of the secondary clarifier:

The clarifier tank is only a passive device. All the above actions occur due to gravity. The thick biomass is reticulated back to the aeration tank. There are three popular design variations in the unmechanized clarifier tank. They differ in the manner in which the sludge is collected and returned to the aeration tank:

Overflow water from the clarifier is collected in an intermediate clarified water sump. This sump acts as a buffer tank between the secondary and the tertiary treatment stages in an STP. In a well-run STP, the treated water quality at this stage is good enough for reuse like perfusion, and water for garden use may be directly taken from this sump, without having to overload the tertiary units.

Filter feed pumps are used to take the water from the clarified water sump and pass it through the pressure sand filter and activated carbon filter installed in series.

An activated carbon filter is a tertiary treatment unit. It receives the water that is already filtered by the pressure sand filter and improves multiple quality parameters of the water.

The treated water is disinfected to destroy and render harmless disease-causing organisms, such as bacteria, viruses, etc. The most common methods of disinfection include chlorination, ozonation, and UV radiation. Of these, chlorine finds widespread application. The primary action of the chemical involves damaging the cell wall, resulting in cell lysis and death.

We offer:

Residential Apartment, Hotel Industry, Pharma Industries, Export House, Automobiles Industries, etc. for Installation, Operation, Maintenance and Cleaning Services with High efficiency, Smooth Functional and Low Maintenance.

Our skilled and experienced team of professionals make easy of your cleaning work.

We offer the Best Rate of cleaning related services at very competitive rates to our clients.

Basic Solution is an Registered company in Haryana that makes your work's Safe & Fast.